Storage Container Doors Aren’t Closing Properly

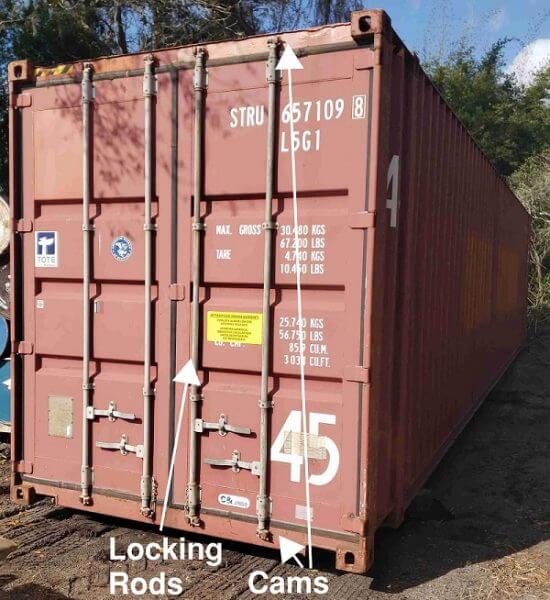

Shipping container doors are not your typical doors, and sometimes they can be stubborn! There are several key components that must line up properly in order to get the doors to close. There are the hinges (usually 4 per door), the locking rods (usually 2 per door), the lock handles & hasps (usually 2 per door), and the cam keepers (at the top and bottom of each locking rod). One of the main reasons that one or both doors of a Conex box will not shut or close evenly is because the unit is not sitting level. When the unit is not level, the locking rods and their counterparts, the cam keepers, will not line up properly. When a container is placed on an uneven surface and one end of the box is sloping in one direction and the other end is sloping in another, this causes the unit to bend or twist. This is sometimes referred to as “racked” and causes the doors to become unaligned. The unlevel surface can also cause twisting in the box which may throw the hinge pins out of alignment which can also cause some trouble with the door freely opening and closing. Containers are engineered to an exact specification and designed to be placed on a flat surface, so it’s crucial to get your conex box level. Sometimes a conex box is not evenly loaded, which can also cause some twisting movement in the box, so make sure your goods are evenly spread.

Fixing Storage Container Doors

Getting your storage container level is the key to making the container doors work properly! An ideal location to set the storage container is on a level concrete pad. However, if this can’t be achieved, the dirt, gravel, or grass can work too. Using scrap wood to level the box out on an uneven surface is another approach. Pressure-treated wood will work best as it won’t crumble outside when it gets wet. Here at American Trailer Rentals, our drivers always check the container doors at delivery to ensure they are working properly. If they’re not, the ATR driver will level out the box.

Prepping Your Site for Storage Container Delivery

Make sure there is plenty of space for the truck. The space required will depend on the size of the storage container. A 20’ storage container requires 60’ of space, and a 40’ storage container requires 100’ of space. The path overhead where the truck drives needs to be clear of any low branches, and at the final location, there needs to be clear overhead space for 16’ so the trailer can tilt upwards. Again, you will want the ground to be as level as possible but also as hard as possible. The truck and trailer weigh quite a bit and will sink in sand, mud, or soggy ground. Lastly, we recommend getting the storage container off the ground so the moisture doesn’t get sucked up into the box. Using pressure treated 6”x6” wood blocks or railroad ties work well for this.